The colour of it will most likely be white. The silkscreen is what will be printed onto the board. (No pad number, no copper) The silkscreen (Documentation printed onto the board) In addition the pad number must also be set to allow the connection between footprint and symbol (between schematic and layout)Īn exception are non plated through holes. (In a typical footprint one sets it to 0 as this is normally handled in the pcb_new project settings.)įor through hole components there is also the drill defined. This is achieved using the clearance settings. Typically this cut-out is larger than the copper feature. Pads are the representation of exposed copper features to which the leads of the component will be soldered.Įxposed copper means that in addition to defining the copper area the pad also needs to define a hole in the so called solder mask. As a first step have a look at the footprint naming guide of the official library Pads (The interface for soldering) For generic footprints include all identifying parameters.

If a footprint is specialized for a single component then include the part number and the manufacturer name. Make sure you include enough information to clearly communicate what the footprint represents. The footprint nameīe careful when naming your footprint.

Defining a courtyard area is also part of a good footprint. It is also suggested to at least include the part outline and part identifiers (reference and value) on the silk and fab layers. At the least it needs to contain so called pads.

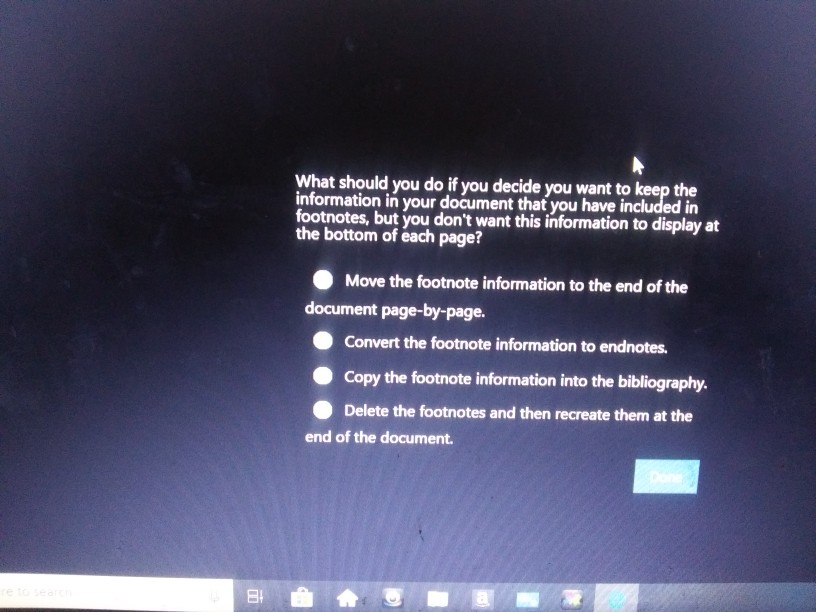

#How to make a footnote show all info plus

Using Inkscape plus Svg2Shenzen to create complex footprints.Especially useful for managing polygon pads.) Kicad StepUp: The Sketcher for Footprint generation (Showcase for exporting footprints directly from freecad.Import/Create FootPrint DXF (Designing a footprint using freecad and a background image).What is the meaning of the layers in pcb_new and in the footprint editor? (KiCad 5 and earlier).

#How to make a footnote show all info how to

0 kommentar(er)

0 kommentar(er)